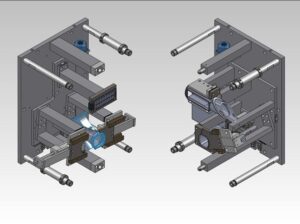

Hot plate welding is a widely used plastic welding process. It is primarily used for multi-contoured part assemblies that require a high strength joint and for it to be hermetically sealed. During the hot plate process two halves of the part are held in precisely machine tooling plates.

A heated platen plate is placed very close to the joint lines of the two parts. Once the material has been heated to its process temperature limit the heated platen plate is quickly removed. The two halves of the material are then precisely driven together to allow the joints to re-solidify. The two halves have now been made into one completely welded part.

Hot Plate Welding is a plastic welding process and provides a high-strength joint and a hermetic seal.

Web Design & Coding by Delphos Digital